TEXTURES.

TEXTURING and repair

Fully in-house elaboration of artwork and texturing supplies for fast response.

Any type of texture or mold. Minor or severe damages. We take care of everything!

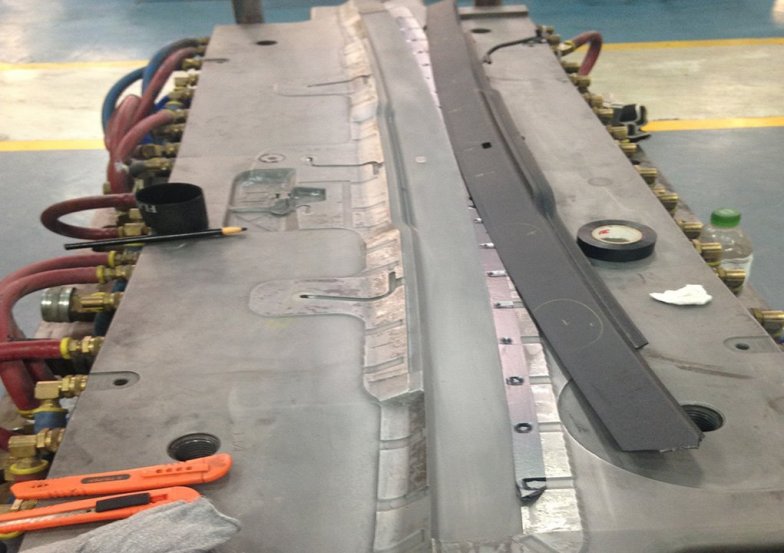

FULL TEXTURING HOME APPLIANCE MOLD WAX PAPER PROCESS

DEFECTIVE AUTOMOTIVE PART.

MOLD REPAIRED SUCCESFULLY

AFTER REPAIR

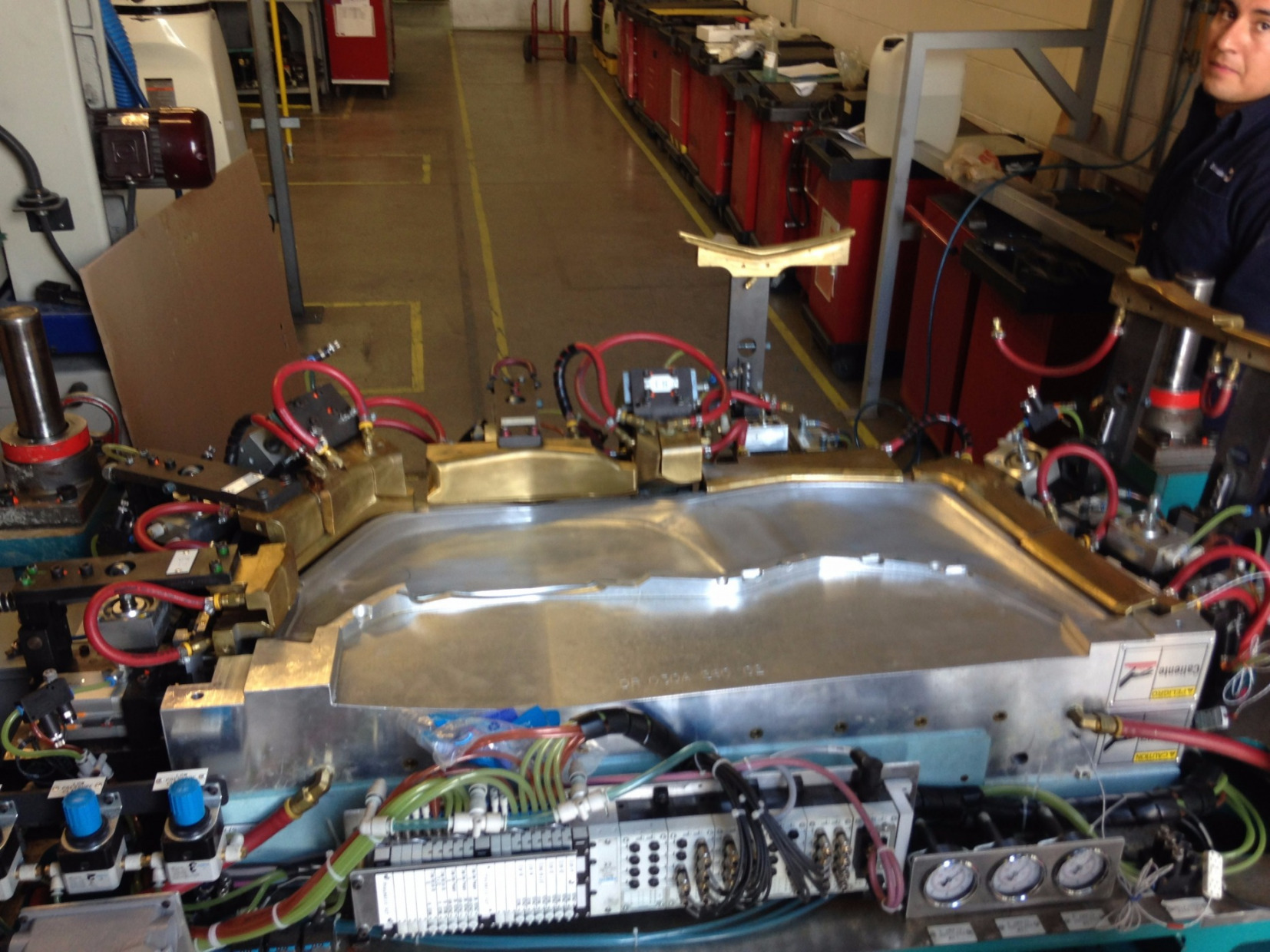

AUTOMOTIVE MOLD FULL TEXTURING

FULL TEXTURING automotive mold

가득 차 있는 조각 및 수리 우리는 조각 또는 금형 유형 사소한 손상이 나 우리가 용접 하 고 마무리 할 주요 손상의 모든 종류를 조각에 대 한 모든 자료를 생산

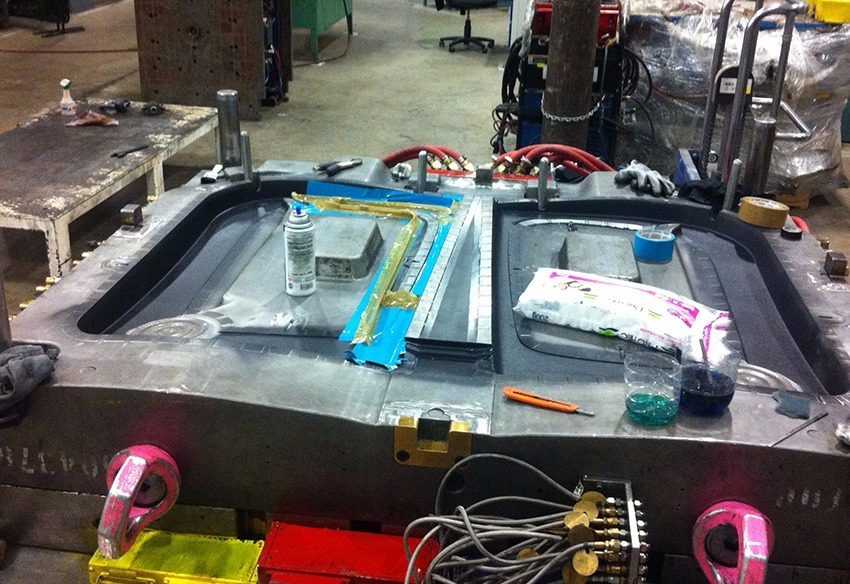

AUTOMOTIVE DOOR MOLD SEVERELY DAMAGED REPAIRED SUCCESFULLY

AUTOMOTIVE MIRROR MOLD SEVERELY DAMAGED REPAIRED SUCCESFULLY

フル彫刻と修理 我々は彫刻のためのすべての材料を生産する あらゆる種類の彫刻または型 軽微な損傷または大きな損傷 私たちは溶接を行い、仕上げる

AUTOMOTIVE MOLD FILM PROCESS

DAMAGE BEFORE REPAIR

APPROVED PART

LOCALIZED COATINGS

WEAR, CORROSION DIMENSIONAL RESTORATION

Aluminum fixture for wrapping an automotive instrument panel. Due to slight geometric errors from manufacturer the wrapping failed adhesion test in several zones. Layers of metal with controlled thickness were chemically applied to solve problem.

This picture shows the zones where the metallization was applied.The thickness at the center is 0.2mm and gradually vanishes outside according to the Customer instructions.

Mold with deformations caused by erosion and low hardness in front of nozzles (defective part shown). They were metallized with a hard alloy and leveled flush without marks normally found with welding or inserts.

고급 차량의 계기판 포장용 알루미늄 고정물. 가공 중 약간의 기하학적 오차로 인해 포장이 여러 영역에서 접착력 테스트에 실패했습니다. 두께 조절이 가능한 경질 금속의 여러 층이 QC 보고서에 따라 화학 공정에 의해 큰 성공을 거두었 다

금속 화가 적용된 구역. 두께는 중앙 (0.2mm)에서 최대이며, QC 보고서에서 지시 한 것처럼 점차 바깥으로 사라지도록 조정됩니다.

플라스틱 제트가 지적한 경도가 낮기 때문에 변형이 일어났습니다 (결함 부분 표시). 그들은 단단한 합금으로 금속 화되었으며 용접 또는 삽입물과 함께 일반적으로 발견되는 흔적없이 평탄하게 수평을 유지합니다.

高度な車のための計器板のためのアルミニウム据え付け品。製造エラーのためにビニールは複数の区域の付着テストに失敗した。調節可能な厚さの堅い金属の層に QC のレポートに従って化学プロセスによって大きい成功があった。

メタライゼーションが施されたゾーンは、中央(0.2mm)で最大であり、QCレポートに示されているように徐々に外側に消えるように調整されています

プラスチックジェットが指し示す低硬度の変形(欠損部分が示されている)によって成形された金型は、硬質合金で金属化され、通常は溶接またはインサートで見られるマークなしで平坦にされた

With our exclusive process of chemical metallization, we can apply a locallized layer of hard metal with extremely good thickness control and adhesion to obtain a proper parting line seal. This is the faster and safer method to eliminate flash

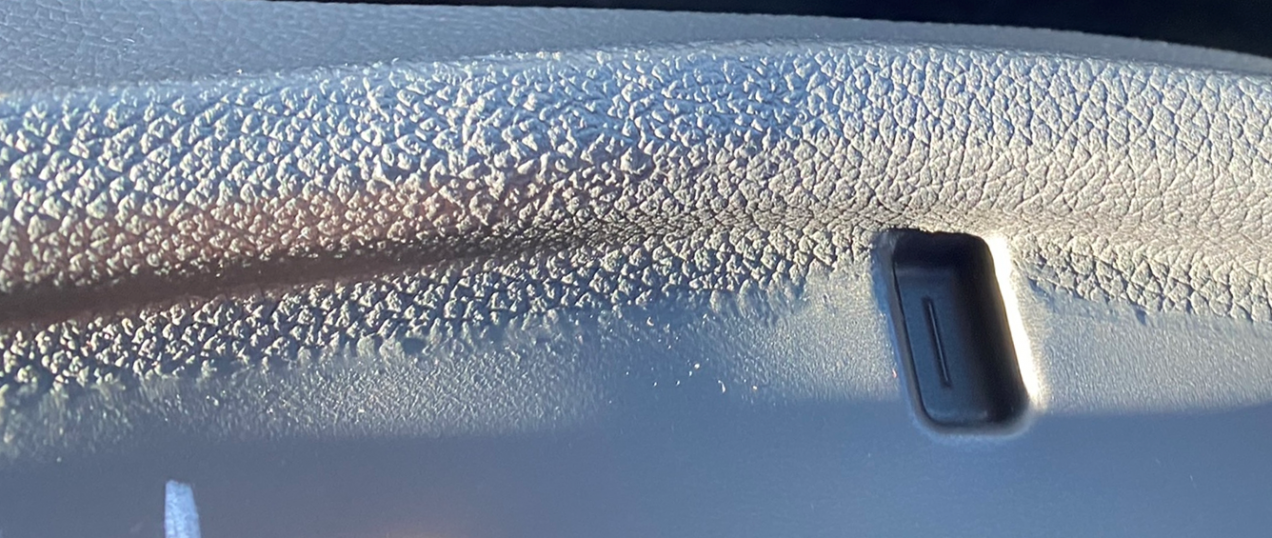

Double mold for door interior. The surface is fully textured with a geometric pattern very difficult to repair if welded. Flashing zones and flash thickness were identified and the corresponding layer of metal was added to obtain zero flash. Work on-site. Time one shift.

독점적 인 화학 용접으로 우리는 적절한 라인 씰을 얻기 위해 매우 우수한 두께 제어와 접착력을 지닌 경질 금속의 로칼 라이즈 된 레이어를 적용 할 수 있습니다

문 내부를 위한 두 배 형. 표면은 완전히 기하학적 인 패턴과 용접으로 수리 하기 어려운 매우 질감이 다. 누수 영역과 플라스틱 두께가 식별 되 고 금속에 대 한 화학적 보증금이 추가 되어 제로 누출을 얻을 수 있습니다. 현장에서 작업 합니다. 시간 1 교대

생산력과 높은 불완전 한 비율의 손실로 정돈 되어야 한 가벼운 트럭의 B 기둥을 위한 형. 2 교대 내의 사이트에 성공적으로 고쳐진

当社独自の化学的メタライズ処理により、非常に良好な厚さの制御と接着性を備えた硬質金属の局所的な層を適用し、適切なパーティングラインシールを得ることができます

ドア内装のためのダブルモールド溶接されたフラッシングゾーンとフラッシュの厚さが確認され、金属の対応する層が追加された場合、幾何学的パターンで表面が完全にテクスチャ加工され、

軽量トラックの柱のための金型は、結果として生産性が損なわれ、2つのシフトで顧客工場で成功裏に修復された不良率が高かった

PARTING LINE FLASH ELIMINATION FOR REDUCTION OF TRIMMING REWORK

Mold for B pillar of light truck that had to be trimmed with consequent loss of productivity and high defective rates. Succesfully repaired on-site within two shifts.

MIRROR POLISHING OF MOLD CAVITIES

REAR AUTO LAMP MOLD INSERT

LARGE AND SMALL INSERTS

TAIL LIGHT MOLD CAVITY

HEADLAMP MOLD CAVITY

ENGRAVING OF CHARACTERS AND MIRROR POLISHING

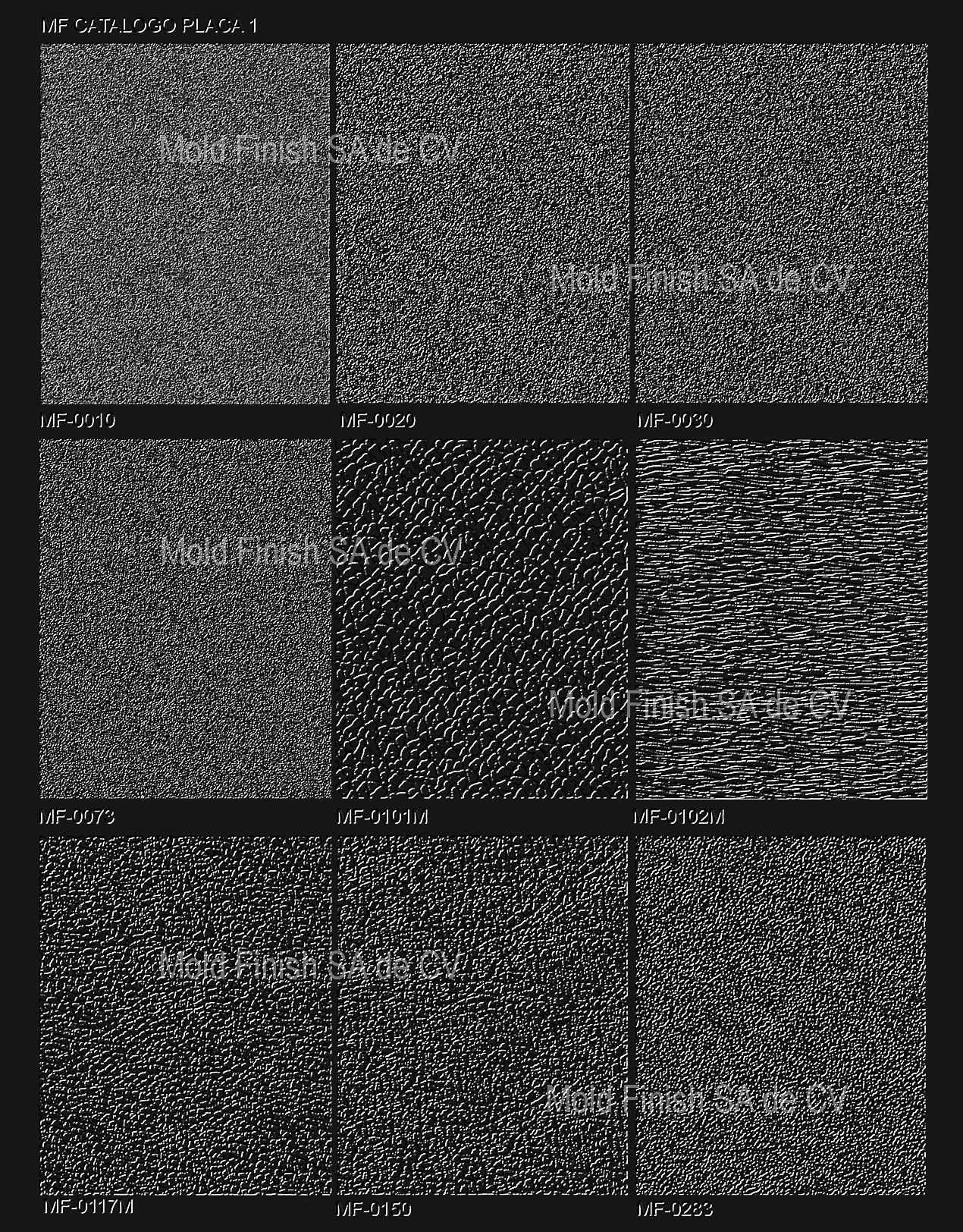

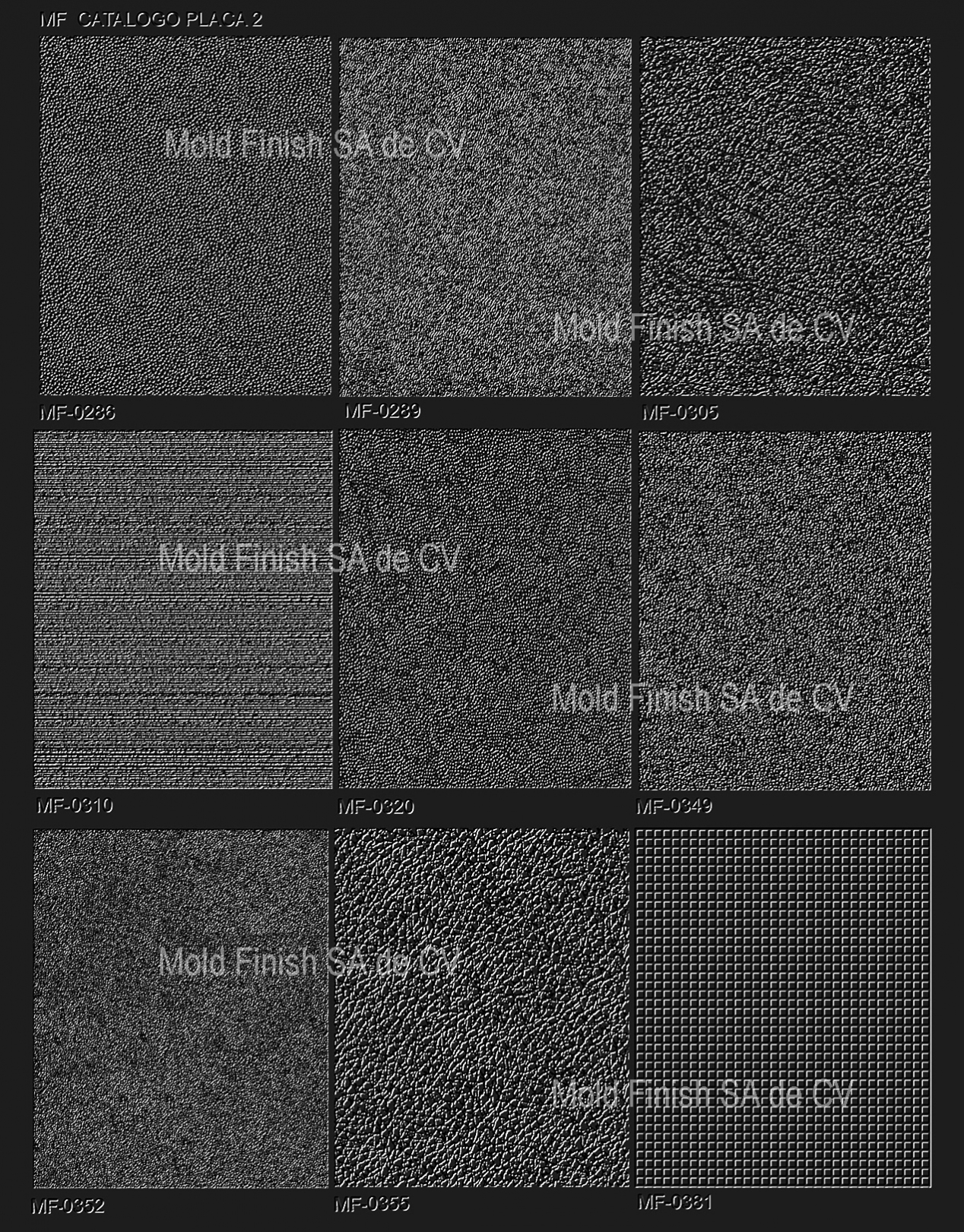

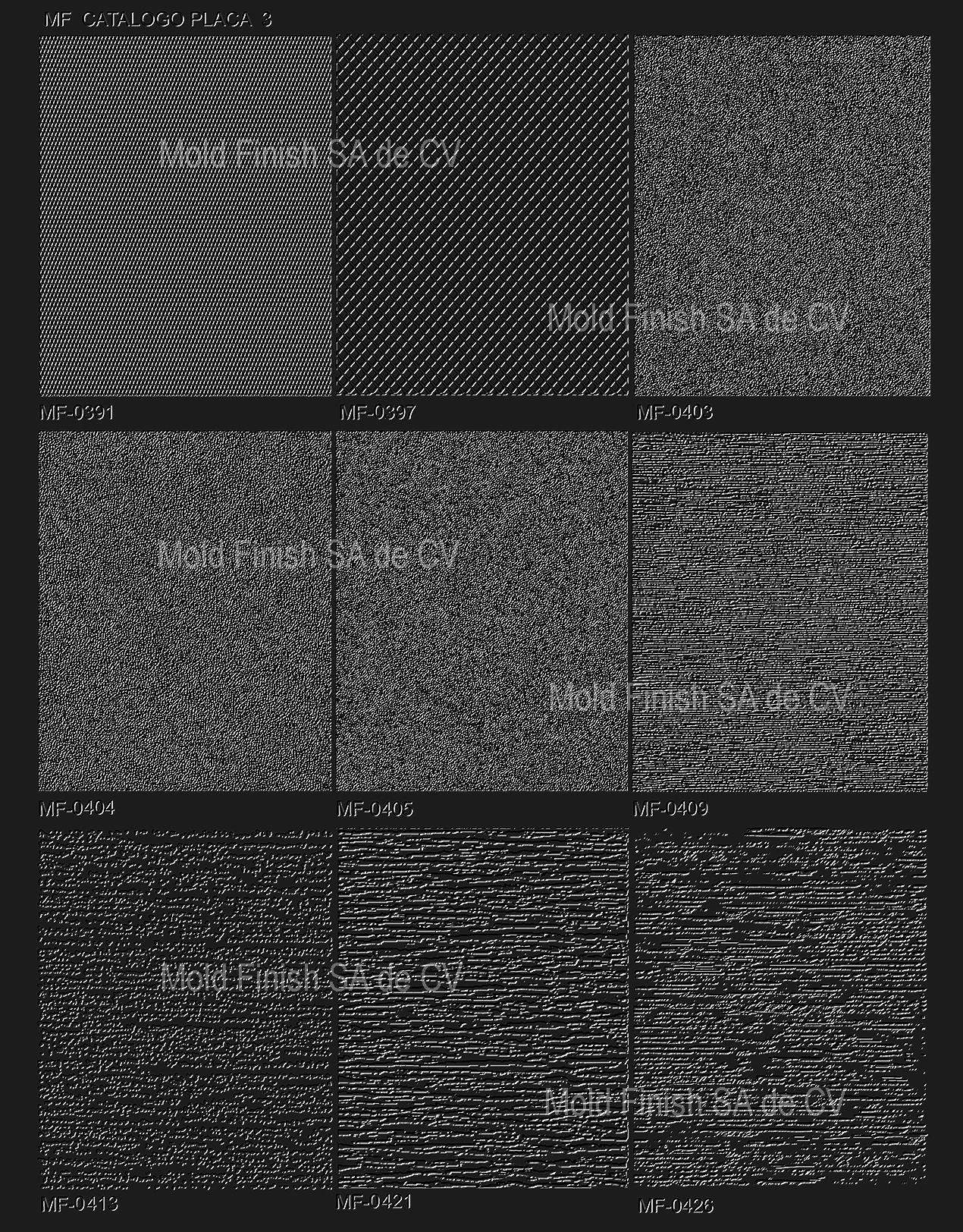

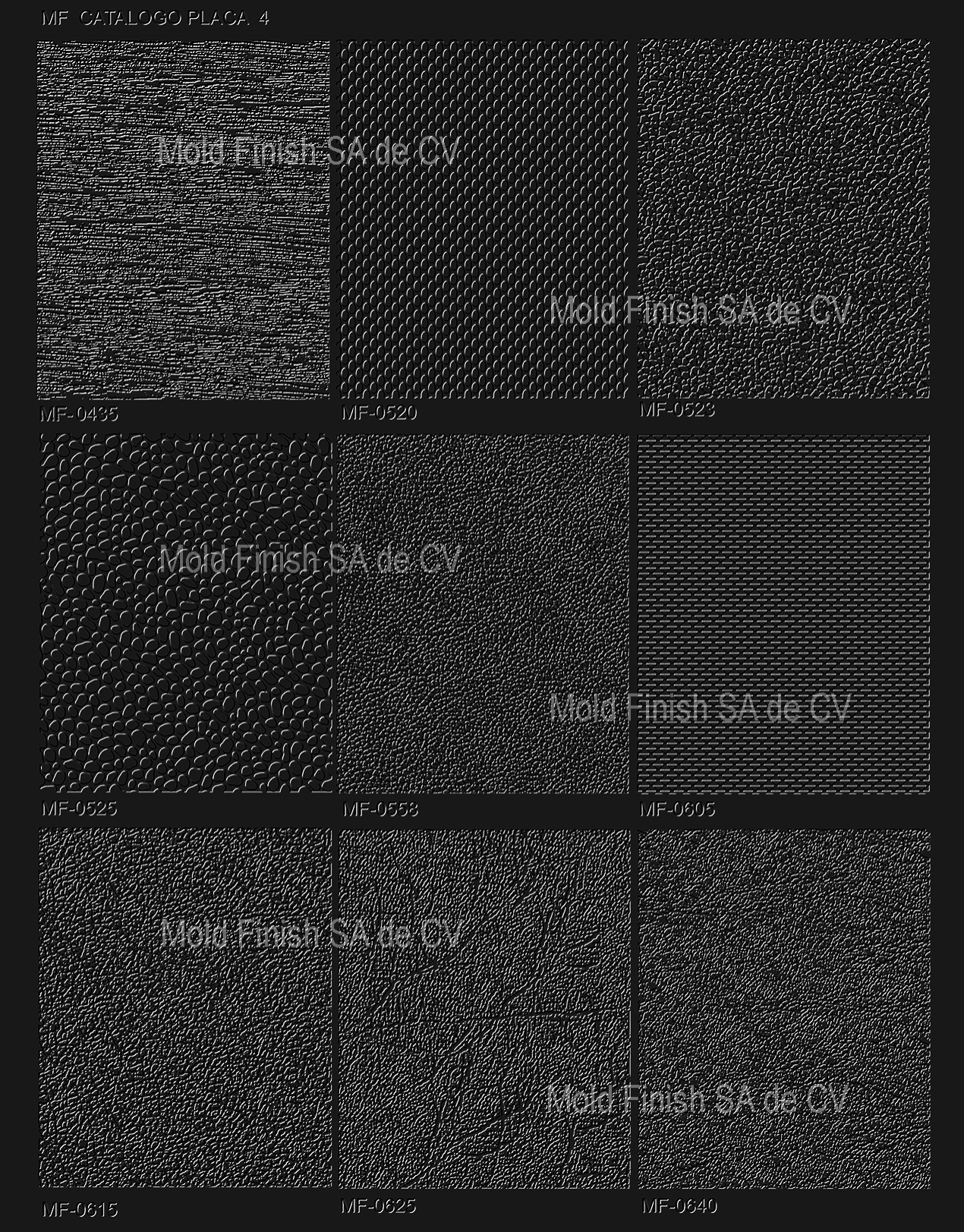

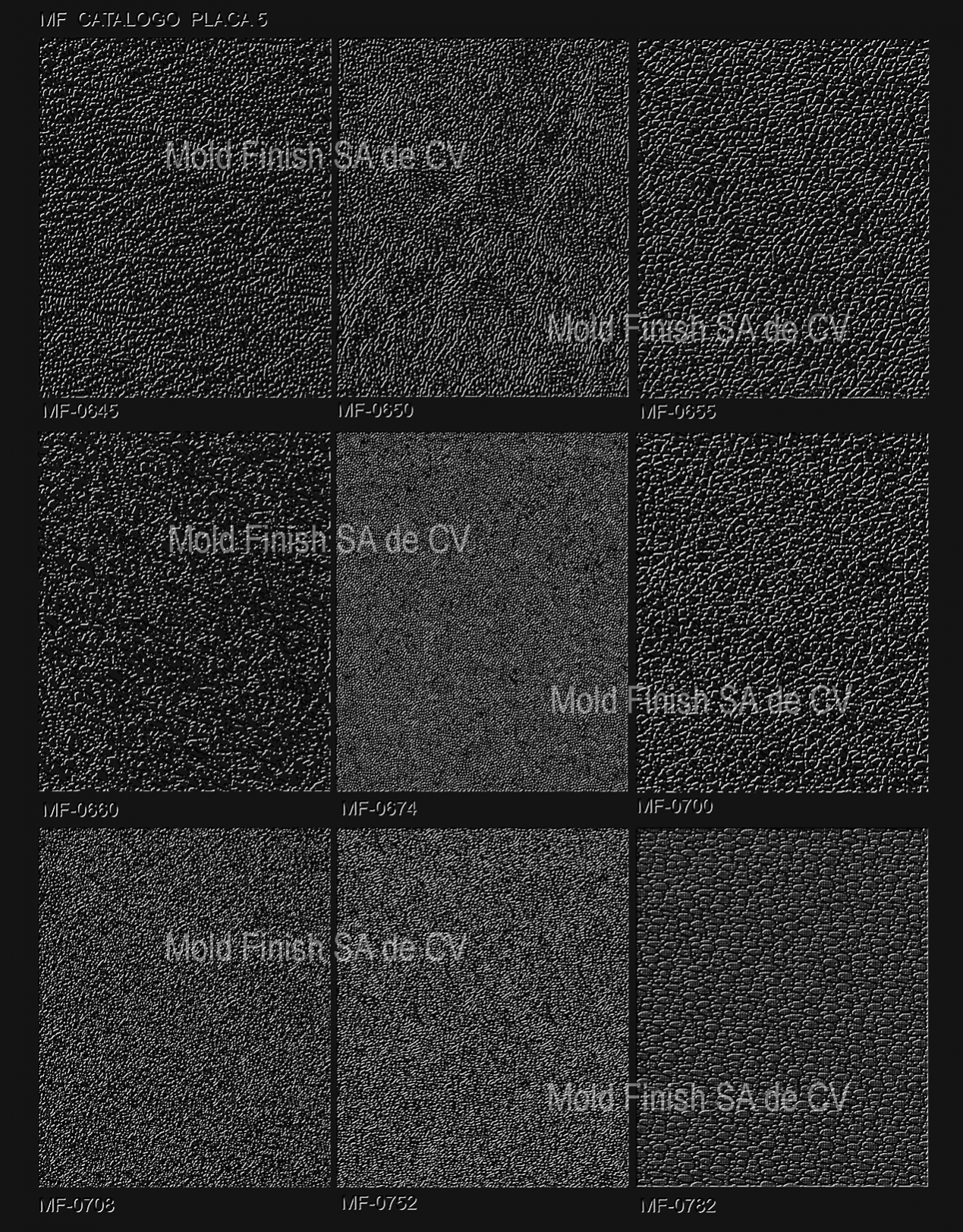

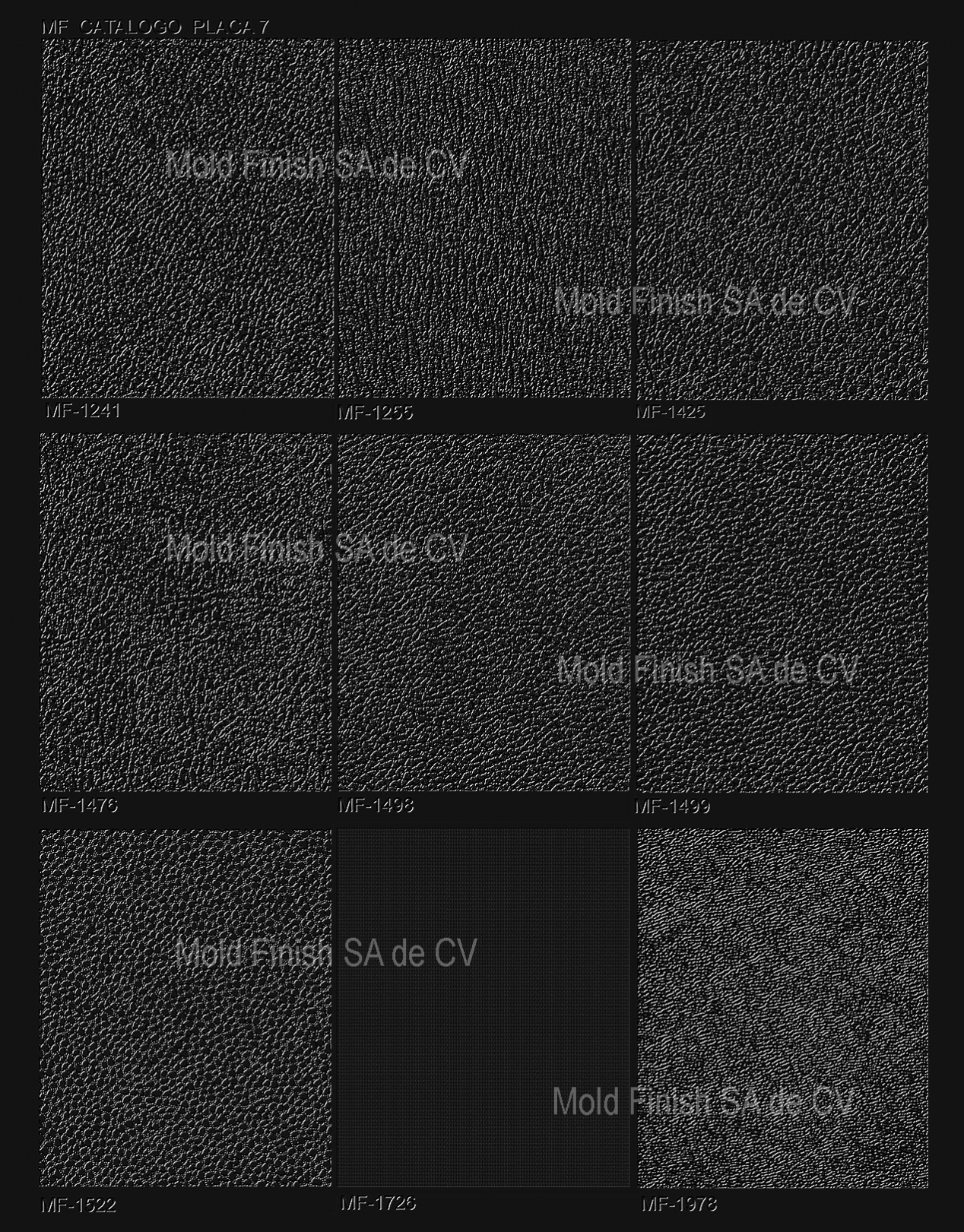

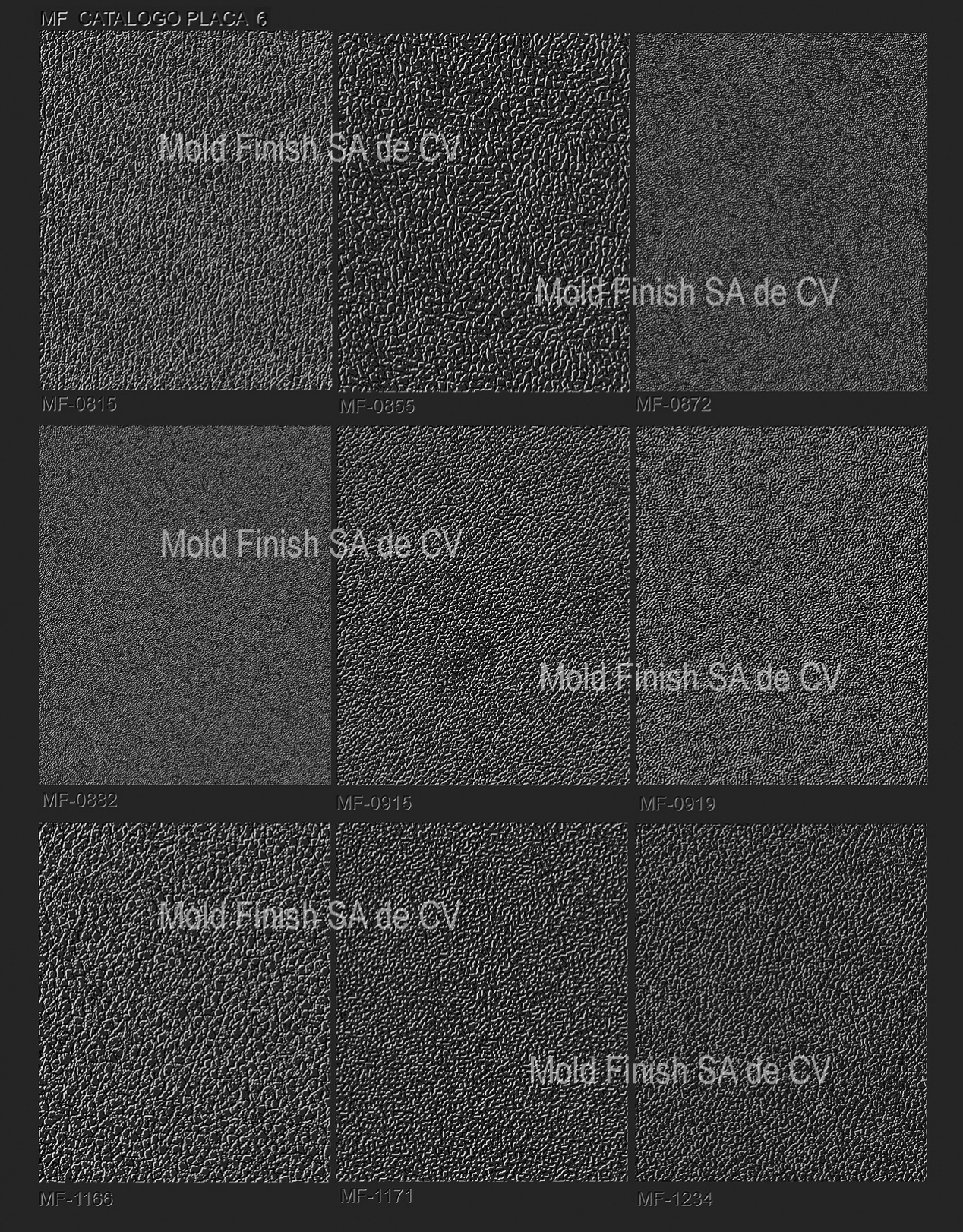

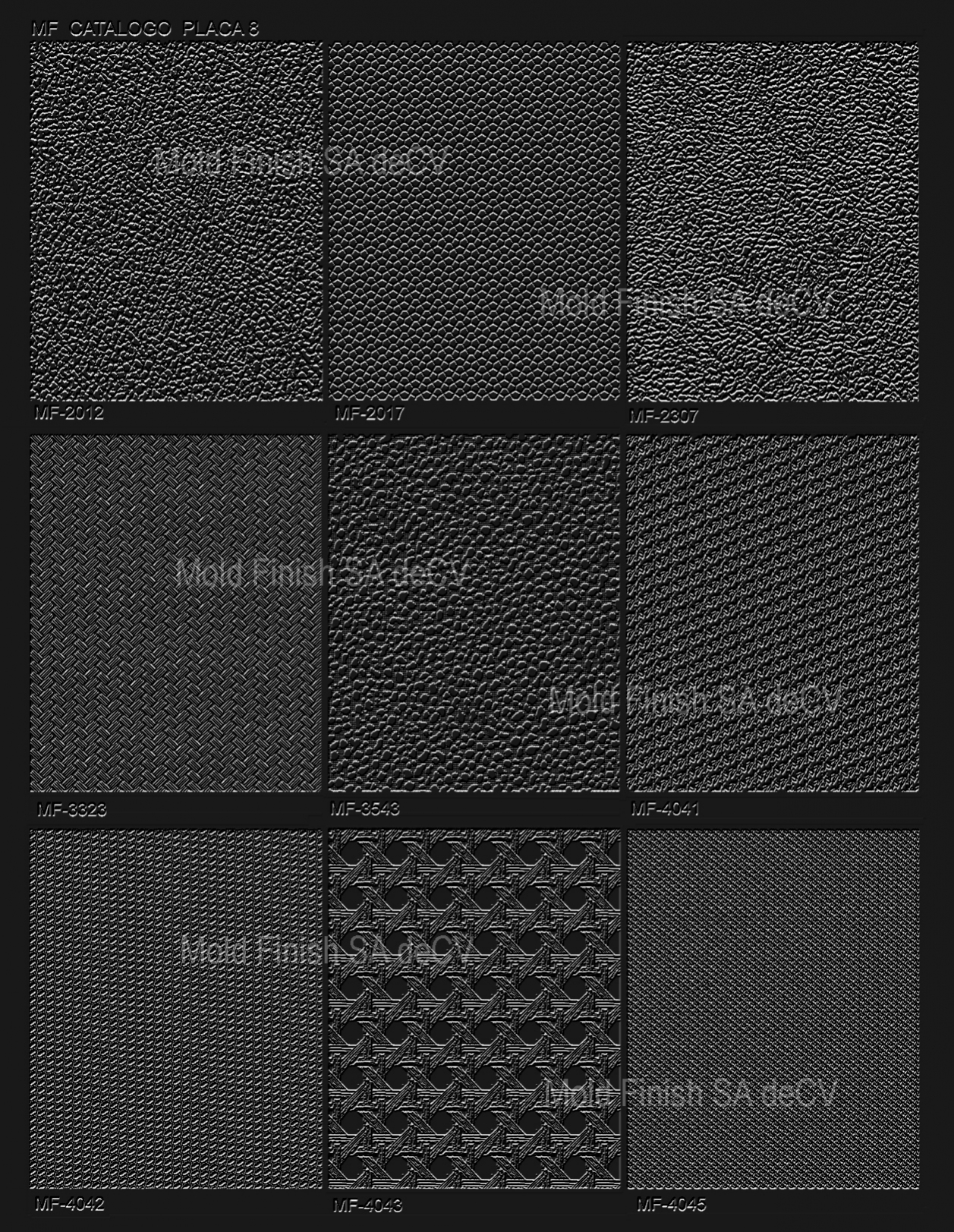

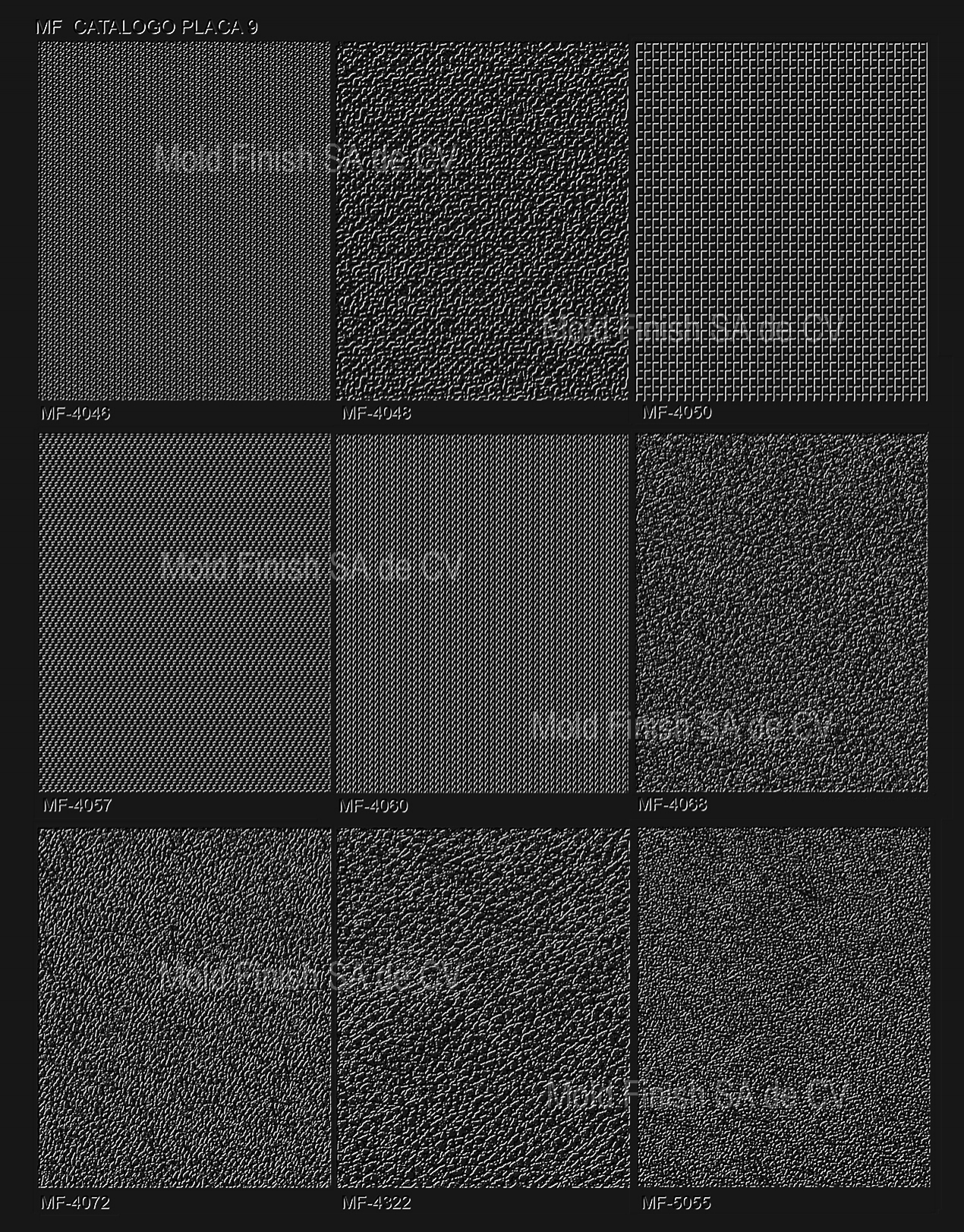

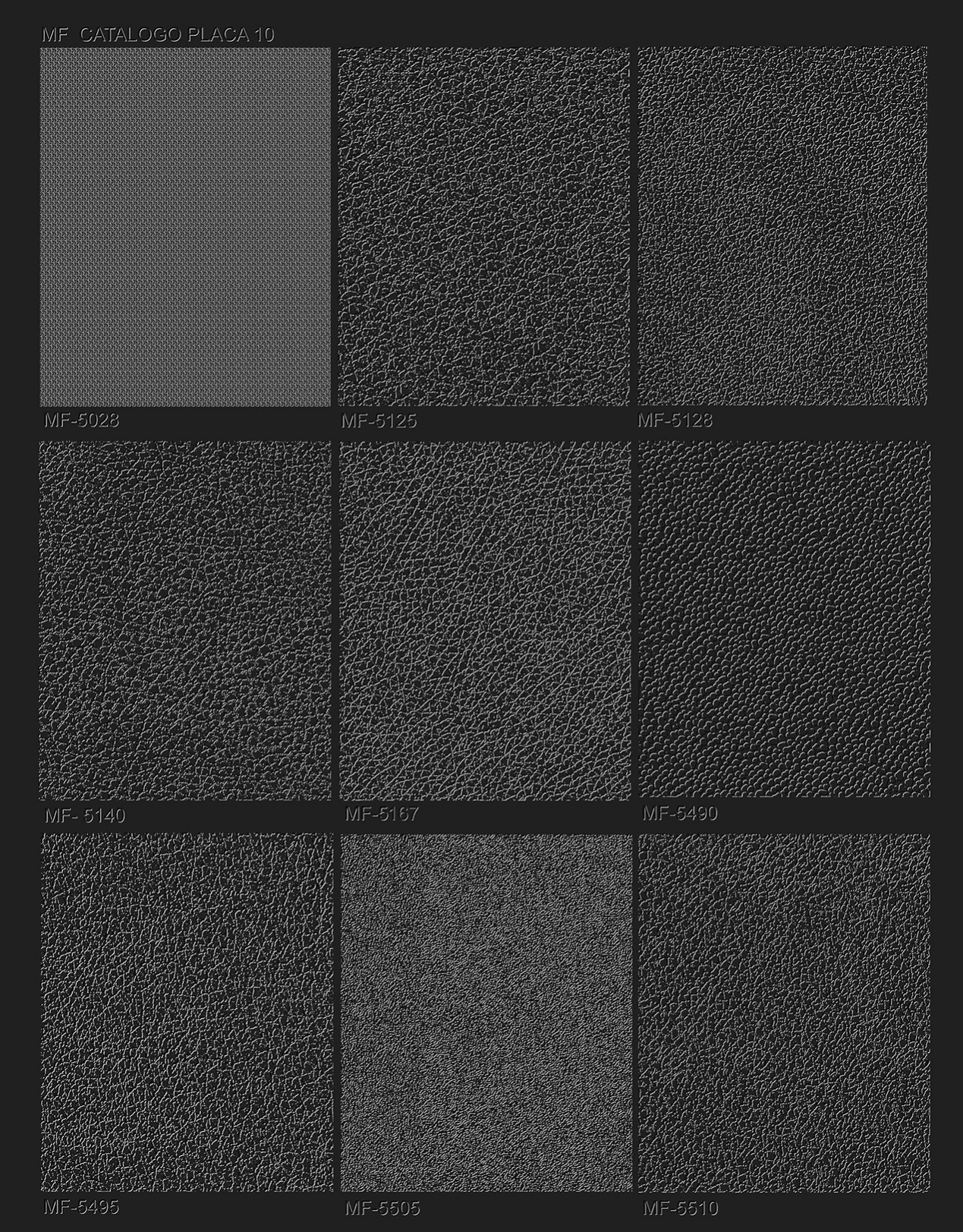

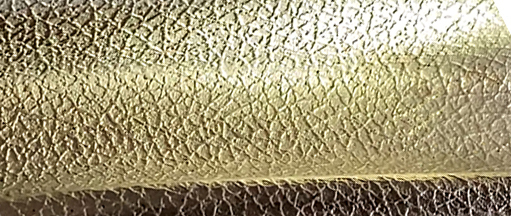

TEXTURE CATALOG PATTERN SAMPLES

We have texture plaques with hundreds of attractive designs to choose from and are constantly developing new patterns according to Customer specifications or samples.

VIDEOS

ELIMINATION OF FLASH THROUGH CHEMICAL DEPOSIT ON AUTOMOTIVE DOOR MOLD PARTING LINE FACE

CHEMICAL DEPOSIT. IN CUSTOMER PLANT. MOLD RETURNED TO PRODUCTION IN 20 HOURS

HAND TRIMMING AND SCRAP DUE TO HUMAN ERROR WAS ELIMINATED ON THESE PARTS

APLICATION OF FILM TO MOLD SURFACE. ALUMINUM MOLD FOR POLYURETHANE AUTOMOTIVE PART

자동차 도어 몰드 파팅 라인면에 화학 물질 증착을 통한 섬광 제거

화학 물질 보증금. 고객 플랜트에서. 몰드는 20 시간 안에 생산으로 되돌아갑니다.

인간의 잘못으로 인한 손질과 긁기는이 부품들에서 제거되었습니다.

금형 표면에 필름을 붙이십시오. 폴리 우레탄 자동차 부품 용 알루미늄 주형

化学的預金。お客様の工場で。金型を20時間で生産に戻す

これらの部品に人間の手によるトリムとスクラップが取り除かれた

ポリウレタン自動車部品用アルミニウム合金への彫刻フィルムの塗布

自動車ドアモール分割線上の化学析出物によるフラッシュの除去

SOME OF OUR CUSTOMERS

ABC GROUP

ANTOLIN

APTIV

AUTOLIV

BOCAR

BRP

DRAEXLMAIER

ELECTROLUX

GE PLASTICS

HELLA

HUSSMAN

HYUNDAI / KIA

IACNA

INTEVA

JONES PLASTIC

JOYSON

KASAI

LEON PLASTIC

LEOPLAST

MABE

MAGNA

PEMSA / CIE

THERMOTECH

VALEO

WHIRLPOOL

YANFENG

ZF

SITUATION

Nickel electroformed molds are difficult to repair even with modern low heat input metHods such as laser or microtig welding. The reduced wall thickness as well as the natural corrosion resistance of the metal pose a challenge to most build-up and etching procedures involved in texture repair.

New high tech porous nickel shells are even more difficult. MOST Experienced technicians consider this repair too risky or impossible. Dozens of micropores per square centimeter with edges only a few tenths of a milimeter are THE CULPRIT.

We are the only company in Mexico with the specialized process and know-how to repair them.

Based on the same electrochemical principle used to produce theSES TOOLS, we apply the necessary layers of metal to fill damages. Room temperature, no damage to surroundings.

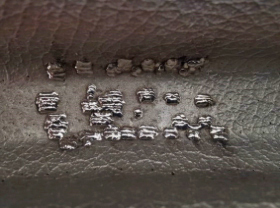

ELECTROFORMED MOLD REPAIR. SOLID / POROUS

Porous nickel shell mold for production of a skin wrap for the instrument panel of a high end vehicle. Foreign object (bolt) trapped caused small damages

Initial damage laser welded.

Several weeks after. Molded part rejected.

Our intervention. Picture of mold surface.

Damages left by the weld spots and acid etching perfectly filled, leveled and textured.

Electrochemical localized deposition of nickel (same method used to manufacture these molds). No heat, only treated areas receive metal. Excellent adhesion and hardness.

OUR REPAIR

COMPETITOR

After several failed attempts many pores opened. More laser spots and acid etching only made problem worst. Job by largest texturing company in the world.

Putty of the repaired zone. Uniform surface and grain. No trace of previous damage